|

|

First, a reinforcing sleeve is made from an 8.5 inch length of 3/4 inch CPVC. This pipe

has an inside diameter of 11/16 inches even though its name implies that it should be 3/4 inches.

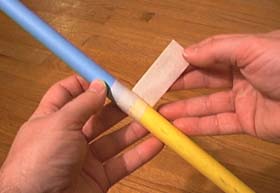

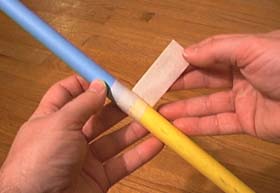

A coupler is glued to one end to act as a crude funnel for adding the sparkler comp. Now take

a coupler for 1/2 inch CPVC and hot glue it to a handle stick as in the picture. This is your

high tech scoop.

|

|

The next step is to make a simple rammer from a 12 inch length of 5/8 inch diameter

dowel. Sand it to remove any rough edges and imperfections and seal it with some kind of

sealer. If your not a perfectionist, you don't even need to bother with the sanding and

sealing. This ram will be quite loose in the tube so precision is not a major concern.

|

|

The composition mix comes from the Desert Blast formula for a 90 second waterfall. The

list of chemicals follows:

- Potassium perchlorate ......................50 parts

- Aluminum, bright ..............................15 parts

- Aluminum, 50-150 mesh, granular.....35 parts

- Dextrin.............................................+8 parts

This mix, when dry, is similar to a very slow flash. It should be treated with due

respect, but no special mixing procedures are required. Enough water is added to just

barely activate the dextrin. This means it will just stick together when squeezed, but

is still quite crumbly and loose.

|

|

Now a common piece of 8.5 by 11 inch copy paper is rolled around the rammer dowel to form

a tube 8.5 inches long. The dowel, with the paper rolled around it, is inserted into the

sleeve tube and the paper is released. The dowel is removed and the sleeve tube is tapped

and bounced a few times so that the natural spring in the paper will cause it to expand to

fit snugly inside the sleeve. Next, the paper tube is pulled about half way out of the

sleeve, just enough to get some glue under the free end of the rolled up paper tube. The

paper is then pushed back into place inside the sleeve.

|

|

An end plug can be made by ramming about 1/2 inch of bentonite clay into the bottom of the

tube. A better alternative is a paper end plug from Skylighter (item #198), but the

drawback is that you have to buy 500 of them at a time. That would be enough to last me

about 49 years. I suppose you could make your own paper end plug, but I'm too lazy to

even consider that option.

|

|

Once the end plug is secure, it's time to start charging the tube with the moistened

sparkler mix. The scoop is first filled and then dumped into the end of the sleeve with

the coupler on it. The scoop will fit inside the coupler and prevent any spillage as it

is gently tapped a few times to encourage the mix to fall out into the paper tube.

|

|

Then the newly added composition is compacted by insertion of the wooden rammer. It may be

rammed a few times by hand pressure or tapped a few time with a light mallet. Extreme

pressure is not necessary because the dextrin binder will do the job of holding everything

together just fine. This cycle is repeated until the tube is full to within 1/16 inch from

the end of the paper tube. Then the loaded tube is pushed out of the sleeve with the aid

of the rammer. At this point the filled tube will still have an unsecured paper flap which

will need to be glued down to keep it from unraveling with handling.

|

|

The above procedure is repeated exactly as above, with one exception. No end plug is

placed in the bottom. Just start right out filling the tube with the moistened

sparkler comp. This is easily done by holding the end of the sleeve against the surface of

your work table as you add the first charge. After ramming, the composition will stay

securely in the tube without an end plug. The remainder of the tube is now charged to

within 1/2 inch of the top. At this point, you have two charged tubes of sparkler mix whose

paper walls are beginning to feel a little bit damp. They are somewhat delicate until they

dry out and become hard. This will take at least three days, so be patient and set them

aside while they dry.

|

|

When dry and hard, the tubes are ready for joining and mounting on a stick. The 1/16

inch cavity in the end of one of your charged tubes must be filled with a joiner mix

that is sticky enough to adhere to the ends of both tubes.

I use a little sparkler mix which has been moistened with 10% nitrocellulose lacquer to

make a tacky paste. This will assure that the first tube will ignite the second tube

before it burns out. This end is butted up against the end of the other tube where the

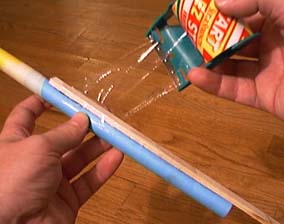

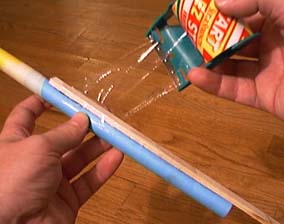

sparkler composition is flush with the end. The ends of the tubes are held tightly together

with a turn of wide masking or packing tape.

|

|

These sparklers are quite difficult to ignite unless you have a good igniter system to

get them going. I can offer several alternatives which work very well. The first one

uses what I call my universal igniter mix. It was given to me by Jim Farrell. Here is

the list of chemicals:

- Strontium Nitrate.......................50 parts

- Parlon........................................18 parts

- Potassium Perchlorate..................8 parts

- Magnalium, 150-200 mesh.........12 parts

- Charcoal, airfloat..........................5 parts

- Sulfur...........................................5 parts

- Red Gum......................................2 parts

A small amount of this dry powder is placed in a small paper cup. A few drops of

acetone is added and stirred until a thick slurry is obtained. Then the stirring

stick is used to dab some of the slurry on the end of the sparkler tube. The slurry

will be very sticky and stringy because the acetone will partially dissolve the

parlon in the mix. I like to poke and stir the sludge to make lots of strings and

fuzzy projections instead of a smooth surfaced blob. This will make the igniter mix

very easy to ignite when it all dries. This ignition method is also pleasing because

it burns with a nice bright red color.

|

|

The other ignition method involves the use of a few short lengths of

home-made thermalite

ignitercord. In this case, two or three lengths of thermalite, cut to a length of

3/4 inches, are placed in the recess of the sparkler tube. Then the recess is filled

with some of the joiner paste mentioned above to hold the thermalite in place. When

finished, the thermalite will protrude about 1/4 inch out of the sparkler tube.

|

|

The last step is to attach the sparkler tube to a suitable stick for a handle. The final

product will look much like a stick rocket except that the ignition end will be pointing

up instead of down. I like to use a generous bead of hot glue augmented by 2 inch wide

packing tape to attach the handle. The stick will be mostly consumed by the hot flame of

the sparkler composition. If you prefer a sturdier, reusable option, a three foot length

of 1/4 inch steel rod with a wooden handle is a good alternative. However, as with

commercial sparklers which use a wire core, care must be taken to avoid burns from the

red hot metal after the sparkler has burned out.

|

|

These "super sparklers" are very pleasing for those of you who like your creations to

last a little longer than usual. They will give you nearly three minutes of enjoyment

provided you don't wave them over your head. They will spit out long lasting, white

hot sparks that will fall to the ground burning. Most of us don't enjoy hot, burning

sparks landing on our heads and burning clear to the skull. I also would counsel against

using these in a field where dry grass or brush could ignite from the falling sparks.

Finally, I will share with you my fantasy about these "super sparklers". The next time

I'm at a neighborhood gathering for the 4th of July and somebody pulls out their wimpy

commercial sparklers, I imagine myself using Crocodile Dundee's line. "That's not a

sparkler.....(I whip out my super sparkler)...Now THAT'S a sparkler!!"

|

|