|

|

I started with a piece of 10 inch wide, plastic surfaced shelf board. You

can buy them for a few bucks at Home Depot or HQ with a wood grain or white

finish. This board has been cut to a length of about 16 inches.

|

|

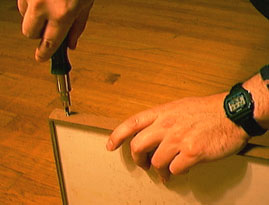

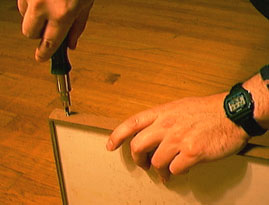

Next, attach edge guides to two sides of the board with screws. The edge guides

should protrude above the cutting surface of the board no more than the

size of the smallest stars you plan to make with this board. I used a few

strips of plastic surfaced paneling for bathrooms. Personal preference is

used to decide which corner of the board you prefer to work in. The sides of

this corner are the ones where the edge guides are attached.

|

|

The star cutting board is complete. To use it, you will need to make a set

of tooling for each size of star you want. To do this, three pieces of gauge

strips are cut from wood or plexiglass. One of these strips is then cut into

two short lengths of about 4.5 inches. The thickness of the gauge strips

is the same as the size of the stars you want to make. The gauge strips

shown are 3/8 inches thick and will yield (real rocket science here) 3/8

inch cut stars. If wood is chosen for the gauge strip material, it

must be sealed with polyurethane and warping may still be a problem.

|

|

The strips are used to border the sheet of dough as you roll it out.

The two strips which contact the edge guides are held stationary by the

guides. The other two are held in place by hand. The short one is adjusted

to the size of the dough batch.

|

|

Now, another piece of plexiglass is glued to a piece of wood to act as a

cutting guide. It is placed with one edge recessed from the bottom, as shown.

The recess should be greater than the star size by about 1/8 inch. The

plexiglass is attached to the wood by several dabs of hot glue which hold

the plexiglass away from the wood by roughly the width of the blade of the

cutting knife which will be used to cut the star dough. The reason for this

will become apparent shortly (if I manage to make myself clear). Again, the

wood should sealed by some means to facilitate cleaning after use.

|

|

To start making a batch of cut stars, I put down a piece of wax paper and

then place the gauge strips on top of it. I then use my hands to roughly

flatten the lump of star dough within the gauge rails.

|

|

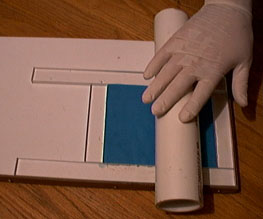

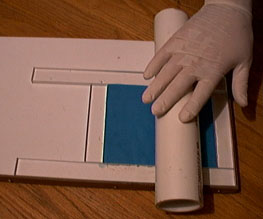

I then use a piece of PVC as a rolling pin to flatten the dough to a very

uniform thickness. If the dough is somewhat sticky, I might use a piece of

waxed paper to cover the dough while rolling. The gauge rails are then removed,

leaving a very well formed rectangular sheet from which to cut strips of star

dough.

|

|

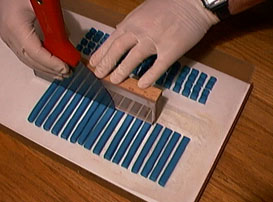

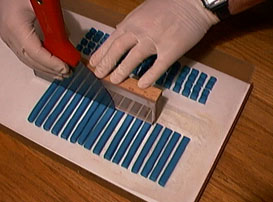

The cutting guide is now used with a wide putty blade to cut the strips.

The guide is designed to assure the cuts are vertical and uniform in width.

To use it, I bring the wooden surface into contact with the dough, as

shown. This is done lightly so the dough is not encouraged to adhere to the

guide. Holding the knife against the plexiglass surface of the guide, I lower

the knife onto the dough and gently mark a line into the surface of the dough.

Then I back away the guide until the knife edge is outside of the mark in the

dough. Now, with downward pressure on the guide to hold it stationary, the

knife is pushed down into the dough to cut off a strip. This cutting action

will force the strip of dough away from the rest of the sheet by exactly the

width of the cutting knife blade. There is room for this to happen without

forcing the dough into the guide because the guide was initially backed away

by this much distance. The whole intent of this procedure is to avoid causing

the dough to stick to the guide or the knife. The severed strip is then slid

or rolled away from the sheet with the cutting knife. Each strip is left

beside the next with a small separation between each one.

|

|

Finally, the cutting guide is again used to cut the strips into cubes.

Unless a different, much longer knife is used, two cutting actions will

need to be performed for each new row of cubes cut from the strips of dough.

If the star dough becomes dry and crumbly before all the cutting is finished,

I often mist the dough with a spray bottle of solvent to keep the dough

moist. When the cutting is done, the wax paper is lifted or slid off the

cutting board with the stars on it and placed on a rack to dry. If priming

is necessary, I usually do this after the stars have dried. In case you're

wondering what kind of bizarre star composition this is, an inert, dyed

salt dough was used to illustrate this marvelous star cutting method. Had

you guessing, didn't I??

|

|