|

|

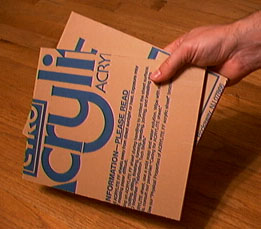

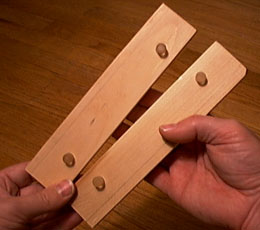

The starting material for this project is 3/8 inch plexiglass. It cost about

$17 for two square feet. Polycarbonate is much stronger, but is nearly double

the cost from my local supplier. I also purchased two 6 foot lengths of 3/8

inch extruded plexiglass rods for $1.35 apiece for the pins of the pin plate.

Shown in this picture are two pieces of the paper faced plexiglass sheet which

have been cut to identical 8 1/8 by 10 1/8 inch rectangles. One side of the

protective paper facing has printed lettering and the other side is blank. The

facing is removed from one side of each sheet and the two exposed surfaces

are placed against each other for fastening together.

|

|

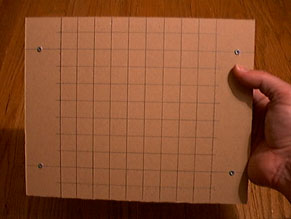

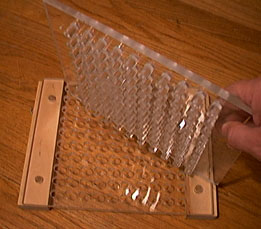

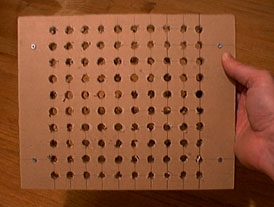

The two plates are securely fastened together with four small wood screws.

This is done by drilling holes through the plates which are just slightly

smaller than the screws. When screwed in, the screws will cut their own

threads without requiring great effort or cracking the plexi. Next, the

hole layout is drawn on the blank paper facing as shown. This is a 10 by

10 matrix of holes with 3/8 inch spacing between them. There will be a 1/2

inch border on the top and bottom and a 1 1/2 inch border on the sides.

You are now ready for the endurance test of your pyro devotion. You must

endure the tedium of drilling 100 holes, cutting 100 pins, gluing 100 pins

and enlarging 100 holes.

|

|

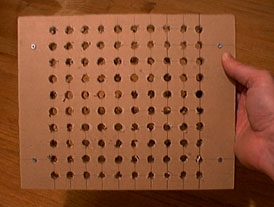

I'm afraid you can't avoid it. You will have to use a drill press

to drill all the holes through the two plates. I wouldn't even consider

trying to do this with a hand drill. Before drilling, a little experimentation

will greatly enhance the likelihood that the pins will not bind in the hole

plate. Using scrap pieces of plate material, drill a hole through two layers

which are securely fastened together. Now check the fit of your pin material

in the hole. I found that a 3/8 inch bit actually drilled a hole slightly

larger than the desired 3/8 inch, probably due to asymmetries in the drill

press chuck. The result is a loose fit of the pin in the pin plate hole. You

may need to experiment with a bit that is 1/64 inch (or more) smaller until a

snug, but not tight fit is achieved. The holes are drilled at the intersections

of the layout marks. It might save you some time centering the intersections

under the drill bit if you use a movable guide rail on the drill press deck.

Here's a reminder of one of the critical tips mentioned in the Svenson article.

Drill every hole with the plate assemby in the same orientation on the drill

press deck. Drill the holes slowly, with light pressure, especially as the bit

is about the exit from the bottom of the two sheets. The friction heat will

soften the plastic and lessen the likelihood of chipping as the bit exits from

the material. When you finish, the attached plates should look like this.

|

|

Now, the remainder of your day is required to cut approximately 110

pin pieces from the plexiglass rounds. Using a radial arm saw with

a stop block will assure that each pin is exactly the same length which,

in this case, is 7/8 inches. The ends of the pins are cleaned up by standing

them all up on their ends on a flat surface. Tape or a rubber band is

wrapped around the bundle of pins to gang them all together in a bunch that

is approximately round. Now a vibrator sander is used to sand off the saw

blade marks. Doing this on both ends of the pins, you should end up with

a bundle that looks something like this picture. If ganging them all up in

one bundle is too taxing on your patience, try smaller bundles of 10 to 20.

|

|

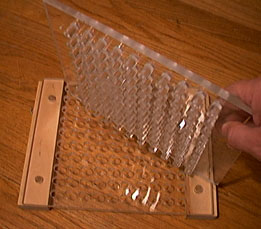

Next, the rest of the paper facing is removed and one's britches are

hitched up in preparation for gluing the pins in the pin plate. (There's

nothing worse than saggy britches while gluing in pins!) The original

bottom plate, from which the drill bit exited during the drilling step, is

designated the pin plate because it is most likely to have a few chip damaged

holes in it. There are several possible approaches to gluing the pins in the

pin plate. If you have the guts to try it, you can use the method illustrated

in the picture. Using medium viscosity cyanoacrylate glue, a meager dab is

applied inside the pin plate hole. The pin is pushed through the still attached

hole plate until it is flush with the surface of the pin plate. The pin is

gently rotated to evenly distribute the glue before it sets in about 10 to

15 seconds. Because the glue is more viscous than the fast setting variety,

it will not wick up the pin and weld the pin into the hole plate. This disaster

is still a real possibility if you loose your concentration and apply too

much glue or place it too far into the hole. The advantage of this method is

that the pins are held into alignment by the hole plate. However, if you are

not willing to take the risk of gluing the two plates together, separate them

and do the gluing with a greater measure of peace of mind. Just remember to

keep track of the original orientation of the two plates when the holes were

drilled. The pins must be glued in so that when the pin plate is pushed into

the hole plate, the two plates will mate in this original orientation. This is

critical! You should have about 10 extra pins in case some of them are too tight

or too loose. Since they are extruded, their diameter tolerance is fairly loose.

Always check the fit before glue is applied.

|

|

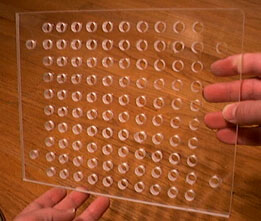

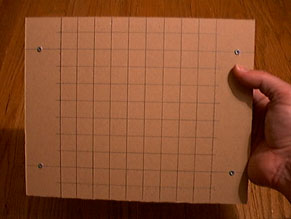

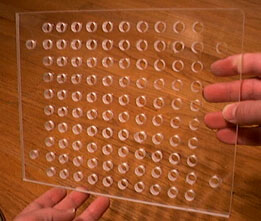

If you didn't remove the fastening screws and separate the plates in the last

step, now is the time to do so. The pin plate is essentially done unless you

desire to cut an inch off of each of the wide margin sides as recommended by

Svenson. I chose not to do this because alignment of the plates during actual

use is easy with a transparent pin plate. The final phase of tedium is the

enlarging of the holes in the hole plate. This step is highly dependent on the

success of the previous steps. Ideally, if all the pins are perfectly aligned,

the holes won't need enlarging at all. In reality, this seldom happens, and the

two plates will stick a little or a lot when trying to mate them together. This

is addressed by enlarging all the holes in 1/64 inch increments. Thus, the first

enlargement is attempted with a drill bit that is 1/64 inch larger than the one

used to drill the original holes. Each hole should be enlarged with the larger

bit centered over the original hole. If this hole enlargement is successful, the

pin plate should fit into the hole plate without binding or requiring a great

deal of effort. Removal should also be fairly smooth. Four stand holes are also

drilled in the hole plate where the original holes for the attachment screws are

located. These holes are drilled with the same bit that is used for the enlarging.

The finished plate should look like the picture.

|

|

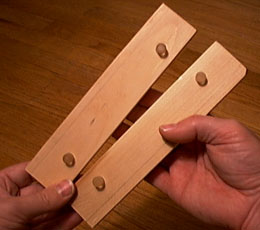

If you have survived the tedium of the aforementioned steps you are now ready to

make a simple stand for the hole plate. This step is a piece of cake. Simply cut

two identical blocks of wood to your liking. If you want your stars to fall a long

distance to their deaths, make them high. I made these from a couple scraps of

3/4 inch pine. One of them is taped in place under the wide border portion on

each end of the hole plate. The stand holes you drilled earlier are now used as

guides to drill a 3/8 hole in two places in each stand block. Using some of your

extra plexiglass pins, glue or tap in 4 of them into the holes in the stand blocks.

Finally, mark all your starplate tooling in some way to make the right orientation

easy to recognize. The Svenson method of nicking off corners is a good idea for

this.

|

|

Here is the completed plexiglass star plate. It's quite a beautiful piece of

artwork as you can see. If your project has been successful, you may now join

the exclusive plexiglass star plate owners guild and be the envy of your whole

neighborhood. Be sure to send a note of appreciation to

Bob Svenson for bringing the star plate within reach of the average back yard pyro

enthusiast. Happy star making.

|

|